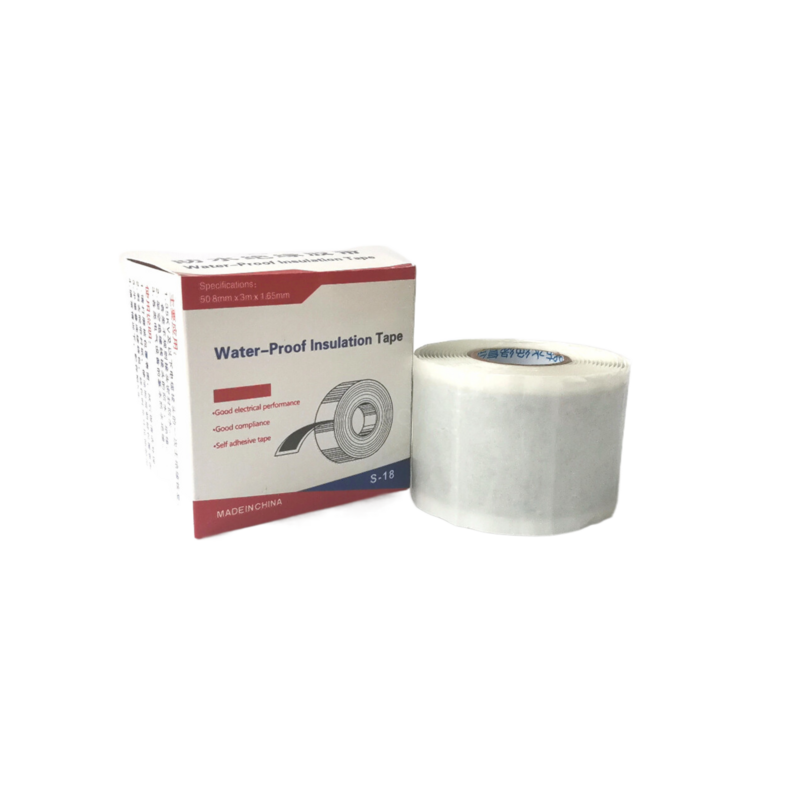

Rubber Electrical Tape. Pads, Helps Protect and Insulate up to 69kV.

flex tape in white. Tape for construction is an essential tool for any building project. From measuring to marking, taping plays a crucial role in ensuring accuracy and efficiency during construction. In this article, we will explore the different types of tape used in construction and their various uses.

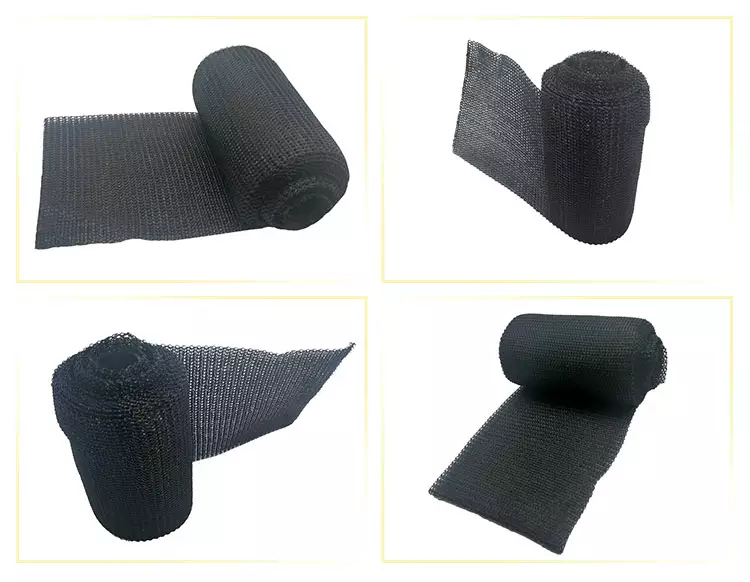

The versatility of Black Flex Tape is evident in its wide range of applications. Here are just a few ways it can be utilized

One of the main uses of 3mm electrical tape is insulating electrical wires and connections. When working with electronics or electrical systems, it is important to ensure that all exposed wires are properly insulated to prevent electrical shocks or short circuits. The thin width of 3mm tape allows for precise wrapping around wires and terminals, creating a secure barrier against electrical currents.

Additionally, self-fusing rubber tape is invaluable in outdoor applications, such as securing gear, bundling tarps, or protecting garden hoses from wear and tear. Its lightweight design and ease of use make it an excellent addition to any toolkit.

5. Chemical Resistance

The ease of application is another factor that makes insulation cotton tape highly desirable among professionals and DIY enthusiasts alike. It is lightweight, flexible, and can be easily cut to size, allowing for a seamless application process. Unlike rigid insulation materials, cotton tape can easily conform to various shapes and surfaces, making it ideal for intricate or irregular installations.

pvc electrical tape factory. They adhere to certifications like UL (Underwriters Laboratories), CE, RoHS, and ISO, ensuring the tape is non-toxic, environmentally friendly, and safe for use in various environments.

pvc electrical tape factory. They adhere to certifications like UL (Underwriters Laboratories), CE, RoHS, and ISO, ensuring the tape is non-toxic, environmentally friendly, and safe for use in various environments.

What's more, its high compressive strength means it can bear heavy loads, making it ideal for mounting items such as mirrors, shelves, and even lightweight fixtures What's more, its high compressive strength means it can bear heavy loads, making it ideal for mounting items such as mirrors, shelves, and even lightweight fixtures

What's more, its high compressive strength means it can bear heavy loads, making it ideal for mounting items such as mirrors, shelves, and even lightweight fixtures What's more, its high compressive strength means it can bear heavy loads, making it ideal for mounting items such as mirrors, shelves, and even lightweight fixtures